Nitrogen Gas Springs: A Cost-Effective Methodology for Precise Manufacturing

Overview

Nitrogen gas springs are widely used in several manufacturing industries involving automotive and aerospace, furniture application and press instruments. They work by using nitrogen gas, which is pale gas that does not react adversely to compression, enclosed in a cylinder. A spring force is generated and conveyed utilizing a piston to a projecting rod. The unit is secured against gas shortages and is totally self-reliant. An excessively high emphasis is given on security, with distinct and patented structures in security components used to protect critical elements from pressure, stroke, unregulated speed, and pollution.

The main justification for using nitrogen gas springs is that they significantly reduce the required surface area and magnitude, which lessens the necessity for preloading and preservation devices. With compact design, it also provides a significant height curtailment for similar operating deviation and force.

Introduction

Nitrogen gas springs are an economical and space-coherent option to conventional metal coil springs in several industrial settings. They are also secure and resistant, providing immediate and evenly distributed pressure across the whole stroke expanse without measurable force loss due to metal fatigue over time. The spring stores energy while gas is forced, and inflated gas pushes the stem upward when pressure is released.

The latest research study on the nitrogen gas springs market estimates the market to record a robust CAGR of 5.7% from 2025 to 2034, owing to the growing demand for progressive suspension techniques in industries such as automotive, aerospace, and bulky machinery where nitrogen gas springs are utilized. The market size for nitrogen gas springs was valued at USD 418.54 million in 2024 and is projected to grow to USD 729.63

million by 2034.

Types of Nitrogen Gas Springs

Free Gas Springs: Free gas springs are the most fundamental types of gas springs. They comprise a cylinder filled with nitrogen gas and a piston that moves spontaneously within the cylinder. The pressurized gas applies a thrust on the piston, generating a push or pull movement based on the outline.

Self-Locking Gas Springs: These gas springs encompass a supplemental locking apparatus that permits them to grasp a particular position without exterior reinforcement. This element is specifically handy in applications where security and accurate positioning are important.

Traction Gas Springs: Unlike conventional contracting gas springs, traction gas springs operate by pulling instead of pushing. When the piston rod is retreated, the interior pressure reduces, and the spring thrusts a pulling force to reclaim its indigenous position. They are especially useful for applications needing regulated repudiation, such as doors, hatches, or even specific kinds of collapsible screens.

Random Stop Gas Springs: These springs can be halted at any instant in their progression. This distinct element is made feasible by a unique procedure that permits the gas springs to lock when the piston rod is impaired and then unlock when the rod is moderately expanded. They are perfect for applications needing manifold or variable halting positions, such as variable desks, monitor stands, and several ergonomic commodities.

Benefits of Selecting the Right Gas Springs

Enhanced Productivity: Gas springs decrease apparatus downtime as they are not susceptible to metallic figure collapse. There are more productive manufacturing instruments as a result of a few spring mechanical collapses, which also show reduced production downtime and lower instrument repair costs.

Improved Safety: Gas springs have a far better workforce security profile because they use an inert gas as the resilient medium. If a gas spring encounters a collapse during functioning, the outcome is a regulated discharge of inert gas. Additionally, gas springs also have supplemental agile security systems that safeguard against over-compelling and overstrike conditions.

Low Maintenance: Nitrogen gas springs need the least maintenance compared to conventional coil springs. Comprising of constituents such as pistons, seals, and fittings encompassed within a cylinder, they require no disinfecting, oiling, or lubrication. Their independent outline eases maintenance as there are no exterior parts to handle.

Challenges Associated with Nitrogen Gas Springs

Computing Force and Size is Intricate: Before making a purchase, one must be informed of the specifics. Some customers decide they need an escort to make an estimate. As a result, specifications must be determined during the project.

Inappropriate for Adapting Force: Since one cannot increase or decrease pressures on their own, one must rearrange a pair that modifies the project if they are purchasing the wrong details of gas springs.

Fear of Leakage Collapse: It is recommended to set aside a 5–10 mm stroke when selecting a nitrogen spring. There is a paint safeguard at the welding process or join framework because of the nitrogen spring joint scenario. Mishap or closeness to the sealing framework throughout the process.

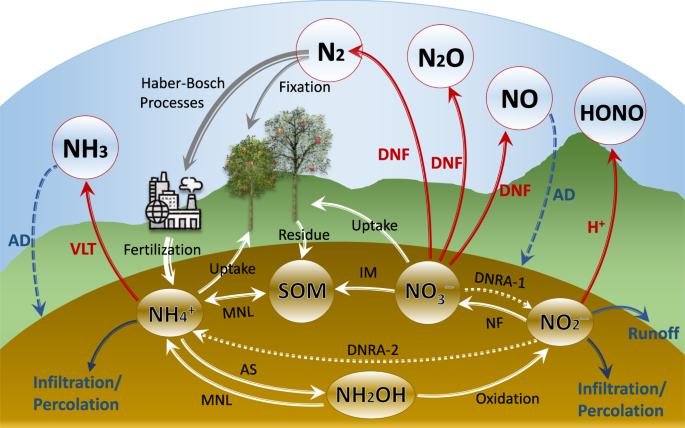

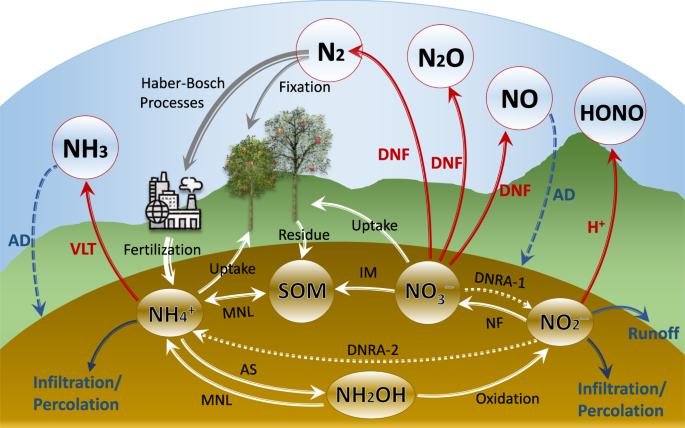

Surplus Nitrogen in the Atmosphere: Surplus nitrogen in the atmosphere can generate contaminants such as ozone and ammonia, which can injure plant growth, resolution, and breathing.

Surplus Nitrogen in Waterways: Surplus nitrogen in waterways and lakes can generate virulent algal blooms, which can harm human well-being and terminate water species.

Conclusion: Nitrogen gas springs have several advantages over other kinds of springs due to their outline and making. They can be utilized in several applications involving office furniture and industrial instruments. They are durable as long as they are utilized under the accurately described conditions. Whether it is offering a lifting force for an automotive trunk, sanctioning the height adaptation of an office chair, or sanctioning the seamless closing of the cabinet door, gas springs execute an important role. By providing a dependable and productive means of handling movement, gas springs improve the usability and durability of commodities covering several industries. As technology develops, so too does the potential and application of gas springs proceeding to enhance the operation and security of several commodities and machinery.

Sources

Ajinkya Shinde

www.polarismarketresearch.com