Description

Abstract:

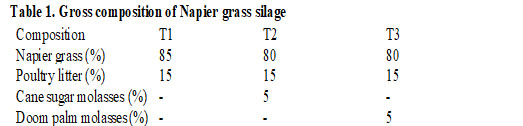

The field experiment was conducted to determine the effects of doom palm and cane sugar molasses on physical and chemical qualities of ensiled Napier grass. A total of fifteen (15) polyehene bags were used for the silage making. The bags were allocated to treatments at five bags per treatment and each bag serves as replicate. T1 as control (ensiled Napier grass without molasses), T2 (ensiled Napier grass with cane sugar molasses) and T3 (ensiled Napier grass with doum palm molasses). Both molasses (doum palm and cane sugar) was diluted with at one liter per four liters of water while the poultry litter was diluted at fifteen-kilogram (15kg) per thirty (30) litres of water which was used at 5% for both types of molasses (doum palm and cane sugar) were diluted while the poultry litter at 15% inclusion level.

The Napier grass was harvested and chopped into 2-3 inches and the molasses, and the poultry litter was sprinkled on the ensiled material and compressed into polythene bags and allowed to stand for 21 days. Exactly at 21 days, the polythene bags were opened and physical parameters such as pH, odour, texture, colour and temperature were recorded. A sample was equally collected from each treatment for proximate analysis. The result obtained revealed that the physical qualities of doum palm treated ensiled Napier grass is comparable with that of cane sugar molasses treated ensiled Napier grass and superior to control treatment. The result further reveals that the CP and NFE (9.54% and 47.54%) of doum palm molasses treated Napier grass were better than cane sugar molasses (8.92% and 46.42%) and control (8.57% and 43.07%). However, the CP values were above the minimum maintenance requirement of 7.5% CP for ruminants. In conclusion, the inclusion of doum palm molasses improved the physical characteristics and chemical composition of the ensiled Napier grass and can replace cane sugar molasses as additive in ensiled Napier grass.

Introduction

Feed resources for ruminant livestock production in the developing countries such as Nigeria normally are natural grass or forage crops, natural pastures and natural feeding has increased rapidly due to its high yielding properties, relatively high energy content, palatability and easy incorporation in total ration (TMR) or total mixed block (TMB) (1,2).

The concept of adding a doom palm molasses is to improve the soluble carbohydrate content of the Napier grass to provide optimum energy requirement of both the animal and rumen microbes for better microbial digestion in rumen and when fed to ruminant livestock improve performance such as meat and milk production (3).

Napier grass (Pennisetum purpureum) can yield more crude protein to meet above maintenance requirement. This grass requires lower inputs and easier to establish than corn and can be a good alternative, especially in production situations that require consistent nutrition on a daily basis. It is for this reason that two silage additives will be tested to find out the effectiveness of preserving the quality of Napier Grass and its effects on growth of sheep (2).

Molasses is one of the feed additives that enhance utilization of unpalatable crop residues and also serves as a good source of soluble carbohydrate. Nowadays, due to competition between the livestock farmers and brewery industry it has now become unaffordable to livestock farmers. Hence, there is a need for developing cane sugar molasses substitute (3,4).

Objective

The main objective of this study is to produce doom palm treated Napier grass silage that can replace the popular cane sugar molasses Napier grass silage. The specific objectives are to:

1 Experimental Site

The Livestock Unit of the Department of farming system research, Lake Chad Research Institute, Maiduguri, Borno State, Nigeria, was the location of the experiment. The semi-arid region lies in West Africa's Sahel zone, which is renowned for its extreme weather and seasonal variations. The area is characterized by a lengthy dry season that lasts from October to May, and a brief wet season that typically lasts from June to September. The warmest months of the year are March, April, and May while the temperature drops significantly during the harmattan months, which takes place between October and February. Extreme temperatures of 43°C and 20°C have been seen in June. August has a relative humidity of roughly 45%, while the drier months of December and January have a relative humidity of roughly 5% (5).

2 Experimental Design

The experiment consists of three (3) treatments laid out in a Completely Randomized Design (CRD) and each treatment allotted with 5 bags serves as replicate making fifteen (15) bags.

3 Doum palm molasses and poultry litter preparation

The doum palm molasses was prepared by 1kg doum palm pulp covered in a 3 litter water and put to boiling for 30 minutes and allowed to cool for about an two hours sieving with sieve size of about 50u and 150 x 100mm size was used. The sieved doom palm molasses was reboiled to attained similar viscosity with cane sugar molasses while sugarcane molasses was obtained from Numan Savana sugar industry, Adamawa state which served as control.

Poultry dropping was source from Maiduguri poultry production unit (PPU). The litter was properly sundried, ground and sieved to remove the bedding material from the poultry litter. Poultry litter was dissolved in water at the rate of 15kg per 30 liters of water.

4 Silage Making

Napier grass was cut at the Lake Chad Research Institute Maiduguri, pasture farm. Doum palm was sourced from Baga market, Maiduguri, Borno state, Nigeria. The Napier grass was wilted for 24 hours and chopped to 3 – 5 cm. The chopped Napier grass and doom palm molasses were mixed at the rates of 1 liter per 5 liters of water while the molasses of same dilution rate to come up with three treatments plus control (Table 1), compressed and poured into polythene bags and allowed to stand for 21 days. At 21 days ensiling, the polythene bags were opened and physical parameters such as pH, temperature, texture, odour and appearance were observed as described by (6). Table 1 displays the proportions in percentage terms.

Results and Discussion

Physical characteristics of the silages

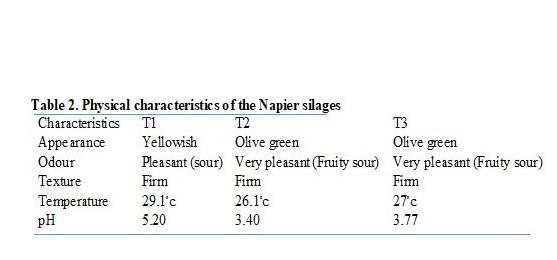

The physical characteristics of Napier grass silage is presented in Table 1. There was a difference in odour, temperature, and pH among the treatments. The silage from T2 and T3 had the same olive-green appearance and was characterized with a very pleasant odour and firm texture. The green olive appearance and firm texture of the silage observed in T2 and T3 is an indication of good quality silage which could be attributed to application of doum palm and cane sugar molasses as a source of soluble carbohydrate. Temperature observed across the treatments in this study was within the ranged (26.1 to 29.1ᶱc).

Temperature of silage above 30ᶱc could be result to silage with dark appearance because of caramelization of soluble carbohydrates in the ensiled material. The pH values ranged (3.40 to 5.20) are within the recommended pH value of (3.50 to 5.50) for superior quality silage (3). The physical characteristics of Napier grass silage observed in this study agreed with the physical characteristics of different varieties of Napier grass silage reported by (7). The physical quality of Napier grass silage observed in this work agrees with the result reported by (3) on quality of ensiled forage.

Proximate composition of Napier grass silage

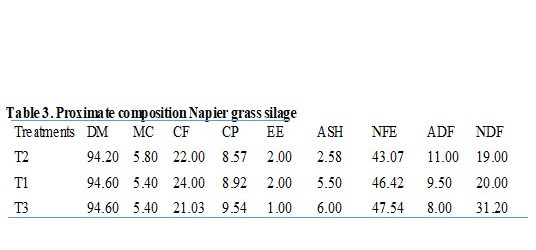

The proximate composition of Napier grass silage is presented in Table 1. The result shows that Dry matter content of all the treatments were high, indicating better storage of nutrients in the feeds (8). The results also reveal that doom palm Napier grass molasses silage with the higher (9.54%) crude protein value while cane sugar molasses Napier grass silage had the similar (8.92%) crude protein with control constituted (8.57%) crude protein above maintenance requirement of ruminant animals.

The crude protein values obtained in this study were above the critical level of 7.5% requirement for minimum performance of ruminants (9), thus doom palm molasses Napier grass silage could be served as a good supplement to augment the available nutrient. The result further indicates that doom palm molasses had the highest (47.54%) while control had the least NFE. This could be attributed to the addition of doom palm in the silage making. The crude value for doom palm molasses-based silage recorded in this study is higher that the crude protein value reported by (10) for Napier grass silage was 8.55% crude protein. The crude protein obtained in this work was also lower than the crude protein reported by (2) for Napier grass silage.

Conclusion

In conclusion, inclusion of doum palm molasses improved the physical characteristics and chemical composition of the ensiled Napier grass. Therefore, doum palm molasses can successfully replace cane sugar molasses as source of soluble carbohydrate.

References

Punzalan, J.K.M. and Rosentrater, K.A. (2024). Copra Meal: A Review of Its Production, Properties, and Prospects. Animals (Basel).14(11):1689. doi: 10.3390/ani14111689. PMID: 38891735; PMCID: PMC11171203.

Bureenok, S., Yuangklang, C., Vasupen, K., Schonewille, J.T. and Kawamoto, Y. (2012). The effects of additives in napier grass silages on chemical composition, feed intake, nutrient digestibility and rumen fermentation. Asian-Australian Journal of Animal Science; 25(9):1248-54

Lamidi, A. A., and Mbah, C.J. (2022). "Nutritional assessment of ensiled fresh maize stover with different proportions of cassava foliage for sustainable ruminant production." Nigerian Journal of Animal Science and Technology 5(1): 53-63.

Mordenti, A.L., Giaretta, E., Campidonico, L., Parazza, P, and Formigoni, A.A. (2021). Review Regarding the Use of Molasses in Animal Nutrition. Animals (Basel).11(1):115. doi: 10.3390/ani11010115. PMID: 33430515; PMCID: PMC7827330.

Adamu, B., Surayya A., Dapellum, A.U., Furo, Y.A., and Muhammed, U.A. (2024). Growth Performance, Carcass Characteristics and Histological Indices of White Fulani (Bunaji) Bull Yearling Calves Fed Graded Levels of Urea and Molasses Ensiled Rice Straw Supplemented with Maize Offal and Cowpea Husk. European Journal of Ecology, Biology and Agriculture, 1(2), 49-62. DOI: 10.59324/ejeba.2024.1 (2). 04

LCRI (2015). Lake Chad Research Institute Annual Report page 3-4

Rambau, M.D., Fushai, F., Callaway, T.R. and Baloyi, J.J. (2022). Dry matter and crude protein degradability of Napier grass (Pennisetum purpureum) silage is affected by fertilization with cow-dung bio-digester slurry and fermentable carbohydrate additives at ensiling. Transl Anim Sci. 23; 6(2): txac075. doi: 10.1093/tas/txac075. PMID: 35769454; PMCID: PMC9225817.

Umami, N. (2023). Silage Quality Based on the Physical and Chemical of Several Napier grass Varieties (Pennisetum purpureum) supplied with different levels of pollard: The 4th International Conference on Agriculture and Bio-industry (ICAGRI-2022), IOP Conf. Series: Earth and Environmental Science 1183 012015 doi:10.1088/1755-1315/1183/1/012015

Akakpo, D.B. (2020). Evaluating the Effects of Storage Condition on Dry Matter Loss and Nutritional Quality of Grain Legume Fodder in West Africa. International School Research Network

Omotoso, O.B., Olatuji, O.A., Obameso, O.O., Odufoye, A., Fejemisin, A.A. and Alokan, A.J. (2020). Nutritional Value and acceptability of some selected forages in the derived savanna zone of Nigeria as Ruminant Feed. Journal of Range and Science, 10(4): 426-433

Mohammed Mustapha

Lake Chad Research Institute, Maiduguri, Borno State, Nigeria

The Napier grass was harvested and chopped into 2-3 inches and the molasses, and the poultry litter was sprinkled on the ensiled material and compressed into polythene bags and allowed to stand for 21 days. Exactly at 21 days, the polythene bags were opened and physical parameters such as pH, odour, texture, colour and temperature were recorded. A sample was equally collected from each treatment for proximate analysis. The result obtained revealed that the physical qualities of doum palm treated ensiled Napier grass is comparable with that of cane sugar molasses treated ensiled Napier grass and superior to control treatment. The result further reveals that the CP and NFE (9.54% and 47.54%) of doum palm molasses treated Napier grass were better than cane sugar molasses (8.92% and 46.42%) and control (8.57% and 43.07%). However, the CP values were above the minimum maintenance requirement of 7.5% CP for ruminants. In conclusion, the inclusion of doum palm molasses improved the physical characteristics and chemical composition of the ensiled Napier grass and can replace cane sugar molasses as additive in ensiled Napier grass.

Introduction

Feed resources for ruminant livestock production in the developing countries such as Nigeria normally are natural grass or forage crops, natural pastures and natural feeding has increased rapidly due to its high yielding properties, relatively high energy content, palatability and easy incorporation in total ration (TMR) or total mixed block (TMB) (1,2).

The concept of adding a doom palm molasses is to improve the soluble carbohydrate content of the Napier grass to provide optimum energy requirement of both the animal and rumen microbes for better microbial digestion in rumen and when fed to ruminant livestock improve performance such as meat and milk production (3).

Napier grass (Pennisetum purpureum) can yield more crude protein to meet above maintenance requirement. This grass requires lower inputs and easier to establish than corn and can be a good alternative, especially in production situations that require consistent nutrition on a daily basis. It is for this reason that two silage additives will be tested to find out the effectiveness of preserving the quality of Napier Grass and its effects on growth of sheep (2).

Molasses is one of the feed additives that enhance utilization of unpalatable crop residues and also serves as a good source of soluble carbohydrate. Nowadays, due to competition between the livestock farmers and brewery industry it has now become unaffordable to livestock farmers. Hence, there is a need for developing cane sugar molasses substitute (3,4).

Objective

The main objective of this study is to produce doom palm treated Napier grass silage that can replace the popular cane sugar molasses Napier grass silage. The specific objectives are to:

- Produce doum palm and cane sugar-based Napier grass silages.

- Determine the physical characteristics of doum palm and cane sugar molasses treated Napier grass silage.

- Assess the proximate composition and pH of the silage produced.

1 Experimental Site

The Livestock Unit of the Department of farming system research, Lake Chad Research Institute, Maiduguri, Borno State, Nigeria, was the location of the experiment. The semi-arid region lies in West Africa's Sahel zone, which is renowned for its extreme weather and seasonal variations. The area is characterized by a lengthy dry season that lasts from October to May, and a brief wet season that typically lasts from June to September. The warmest months of the year are March, April, and May while the temperature drops significantly during the harmattan months, which takes place between October and February. Extreme temperatures of 43°C and 20°C have been seen in June. August has a relative humidity of roughly 45%, while the drier months of December and January have a relative humidity of roughly 5% (5).

2 Experimental Design

The experiment consists of three (3) treatments laid out in a Completely Randomized Design (CRD) and each treatment allotted with 5 bags serves as replicate making fifteen (15) bags.

3 Doum palm molasses and poultry litter preparation

The doum palm molasses was prepared by 1kg doum palm pulp covered in a 3 litter water and put to boiling for 30 minutes and allowed to cool for about an two hours sieving with sieve size of about 50u and 150 x 100mm size was used. The sieved doom palm molasses was reboiled to attained similar viscosity with cane sugar molasses while sugarcane molasses was obtained from Numan Savana sugar industry, Adamawa state which served as control.

Poultry dropping was source from Maiduguri poultry production unit (PPU). The litter was properly sundried, ground and sieved to remove the bedding material from the poultry litter. Poultry litter was dissolved in water at the rate of 15kg per 30 liters of water.

4 Silage Making

Napier grass was cut at the Lake Chad Research Institute Maiduguri, pasture farm. Doum palm was sourced from Baga market, Maiduguri, Borno state, Nigeria. The Napier grass was wilted for 24 hours and chopped to 3 – 5 cm. The chopped Napier grass and doom palm molasses were mixed at the rates of 1 liter per 5 liters of water while the molasses of same dilution rate to come up with three treatments plus control (Table 1), compressed and poured into polythene bags and allowed to stand for 21 days. At 21 days ensiling, the polythene bags were opened and physical parameters such as pH, temperature, texture, odour and appearance were observed as described by (6). Table 1 displays the proportions in percentage terms.

Results and Discussion

Physical characteristics of the silages

The physical characteristics of Napier grass silage is presented in Table 1. There was a difference in odour, temperature, and pH among the treatments. The silage from T2 and T3 had the same olive-green appearance and was characterized with a very pleasant odour and firm texture. The green olive appearance and firm texture of the silage observed in T2 and T3 is an indication of good quality silage which could be attributed to application of doum palm and cane sugar molasses as a source of soluble carbohydrate. Temperature observed across the treatments in this study was within the ranged (26.1 to 29.1ᶱc).

Temperature of silage above 30ᶱc could be result to silage with dark appearance because of caramelization of soluble carbohydrates in the ensiled material. The pH values ranged (3.40 to 5.20) are within the recommended pH value of (3.50 to 5.50) for superior quality silage (3). The physical characteristics of Napier grass silage observed in this study agreed with the physical characteristics of different varieties of Napier grass silage reported by (7). The physical quality of Napier grass silage observed in this work agrees with the result reported by (3) on quality of ensiled forage.

Proximate composition of Napier grass silage

The proximate composition of Napier grass silage is presented in Table 1. The result shows that Dry matter content of all the treatments were high, indicating better storage of nutrients in the feeds (8). The results also reveal that doom palm Napier grass molasses silage with the higher (9.54%) crude protein value while cane sugar molasses Napier grass silage had the similar (8.92%) crude protein with control constituted (8.57%) crude protein above maintenance requirement of ruminant animals.

The crude protein values obtained in this study were above the critical level of 7.5% requirement for minimum performance of ruminants (9), thus doom palm molasses Napier grass silage could be served as a good supplement to augment the available nutrient. The result further indicates that doom palm molasses had the highest (47.54%) while control had the least NFE. This could be attributed to the addition of doom palm in the silage making. The crude value for doom palm molasses-based silage recorded in this study is higher that the crude protein value reported by (10) for Napier grass silage was 8.55% crude protein. The crude protein obtained in this work was also lower than the crude protein reported by (2) for Napier grass silage.

Conclusion

In conclusion, inclusion of doum palm molasses improved the physical characteristics and chemical composition of the ensiled Napier grass. Therefore, doum palm molasses can successfully replace cane sugar molasses as source of soluble carbohydrate.

References

Punzalan, J.K.M. and Rosentrater, K.A. (2024). Copra Meal: A Review of Its Production, Properties, and Prospects. Animals (Basel).14(11):1689. doi: 10.3390/ani14111689. PMID: 38891735; PMCID: PMC11171203.

Bureenok, S., Yuangklang, C., Vasupen, K., Schonewille, J.T. and Kawamoto, Y. (2012). The effects of additives in napier grass silages on chemical composition, feed intake, nutrient digestibility and rumen fermentation. Asian-Australian Journal of Animal Science; 25(9):1248-54

Lamidi, A. A., and Mbah, C.J. (2022). "Nutritional assessment of ensiled fresh maize stover with different proportions of cassava foliage for sustainable ruminant production." Nigerian Journal of Animal Science and Technology 5(1): 53-63.

Mordenti, A.L., Giaretta, E., Campidonico, L., Parazza, P, and Formigoni, A.A. (2021). Review Regarding the Use of Molasses in Animal Nutrition. Animals (Basel).11(1):115. doi: 10.3390/ani11010115. PMID: 33430515; PMCID: PMC7827330.

Adamu, B., Surayya A., Dapellum, A.U., Furo, Y.A., and Muhammed, U.A. (2024). Growth Performance, Carcass Characteristics and Histological Indices of White Fulani (Bunaji) Bull Yearling Calves Fed Graded Levels of Urea and Molasses Ensiled Rice Straw Supplemented with Maize Offal and Cowpea Husk. European Journal of Ecology, Biology and Agriculture, 1(2), 49-62. DOI: 10.59324/ejeba.2024.1 (2). 04

LCRI (2015). Lake Chad Research Institute Annual Report page 3-4

Rambau, M.D., Fushai, F., Callaway, T.R. and Baloyi, J.J. (2022). Dry matter and crude protein degradability of Napier grass (Pennisetum purpureum) silage is affected by fertilization with cow-dung bio-digester slurry and fermentable carbohydrate additives at ensiling. Transl Anim Sci. 23; 6(2): txac075. doi: 10.1093/tas/txac075. PMID: 35769454; PMCID: PMC9225817.

Umami, N. (2023). Silage Quality Based on the Physical and Chemical of Several Napier grass Varieties (Pennisetum purpureum) supplied with different levels of pollard: The 4th International Conference on Agriculture and Bio-industry (ICAGRI-2022), IOP Conf. Series: Earth and Environmental Science 1183 012015 doi:10.1088/1755-1315/1183/1/012015

Akakpo, D.B. (2020). Evaluating the Effects of Storage Condition on Dry Matter Loss and Nutritional Quality of Grain Legume Fodder in West Africa. International School Research Network

Omotoso, O.B., Olatuji, O.A., Obameso, O.O., Odufoye, A., Fejemisin, A.A. and Alokan, A.J. (2020). Nutritional Value and acceptability of some selected forages in the derived savanna zone of Nigeria as Ruminant Feed. Journal of Range and Science, 10(4): 426-433

Mohammed Mustapha

Lake Chad Research Institute, Maiduguri, Borno State, Nigeria

Open Access

Filling the gap between research and communication ARCC provide Open Access of all journals which empower research community in all the ways which is accessible to all.

Products and Services

We provide prime quality of services to assist you select right product of your requirement.

Support and Policies

Finest policies are designed to ensure world class support to our authors, members and readers. Our efficient team provides best possible support for you.

Follow us